Science

Korean Researchers Develop Eco-Friendly Heat-Dissipating Material

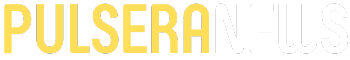

A research team from the Korea Institute of Materials Science (KIMS), led by Dr. Hyun-Ae Cha, has successfully developed a new heat-dissipating composite material that balances environmental sustainability with cost-effective processing. This innovation utilizes a protein foaming technique inspired by egg whites to create a three-dimensional structure of magnesium oxide (MgO), which significantly enhances thermal conductivity.

The new composite material exhibits a thermal conductivity of 17.19 W/m·K, which is up to 2.6 times greater than conventional heat-dissipating composites. As electronic devices become more powerful and compact, they generate increasing amounts of heat, necessitating advanced thermal management solutions. This is particularly critical in electric vehicles (EVs), where inadequate battery cooling can lead to performance issues and safety hazards, including fires.

Typically, thermal interface materials (TIMs) are produced by mixing thermally conductive fillers into a polymer matrix. This traditional method often results in irregular filler dispersion, disrupting thermal pathways and limiting performance. Increasing filler content to enhance conductivity can complicate processing and escalate costs, thus hampering scalability.

To overcome these limitations, the KIMS team employed a novel protein foaming method. By taking advantage of the properties of egg-white proteins that expand under heat, they created a dense and uniform network of interconnected particles. This innovation allows for uninterrupted thermal pathways, resulting in superior heat dissipation capabilities.

The development of this composite not only outperforms widely used materials such as aluminum oxide (Al2O3) but also outstrips nitride-based alternatives. Furthermore, by integrating the material with epoxy resin, typically utilized to improve adhesion with thermal fillers, the team has produced a composite that is practical for real-world applications.

With Korea’s domestic market for TIMs projected to exceed KRW 200 billion annually, the potential impact of this technology is substantial. Currently, the market relies heavily on imports, making this advancement crucial for enhancing Korea’s technological self-reliance in thermal management materials.

Dr. Cha emphasized the significance of this research, stating, “Through the protein foaming–based process, we can produce high–thermal–conductivity materials in an eco-friendly and cost-effective way.” She further noted, “This study serves as a strong example demonstrating the feasibility of developing lightweight, high-performance heat-dissipating materials.”

The findings from this research were published on May 28, 2023, in the esteemed journal Advanced Science, which has an impact factor of 15.1. The article was also selected as the cover piece for Volume 12, Issue 33, highlighting its relevance and importance in the field.

The research received funding from the National Research Foundation of Korea (NRF) under the Nano Materials Technology Development Program, underscoring the support for innovative materials research within the country.

-

Science3 weeks ago

Science3 weeks agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Top Stories2 months ago

Top Stories2 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

World2 months ago

World2 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

World2 months ago

World2 months agoMass Production of F-35 Fighter Jet Drives Down Costs

-

World2 months ago

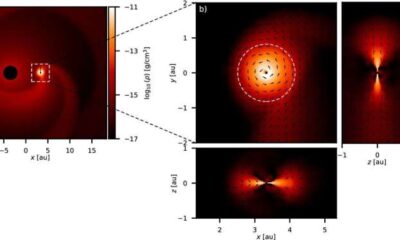

World2 months agoElectrification Challenges Demand Advanced Multiphysics Modeling

-

Politics1 month ago

Politics1 month agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

Business2 months ago

Business2 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Science2 months ago

Science2 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Top Stories2 months ago

Top Stories2 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Entertainment2 months ago

Entertainment2 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Business2 months ago

Business2 months agoUS Government Denies Coal Lease Bid, Impacting Industry Revival Efforts

-

Health2 months ago

Health2 months agoGavin Newsom Critiques Trump’s Health and National Guard Plans