Science

MIT Launches New Manufacturing Education Program Nationwide

The Massachusetts Institute of Technology (MIT) has unveiled a significant initiative aimed at enhancing manufacturing education across the United States. This fall, the Institute introduced the Technologist Advanced Manufacturing Program (TechAMP), a 12-month certificate program designed to equip workers with essential production skills. Developed with funding from the U.S. Department of Defense, TechAMP aims to address gaps in the workforce by providing a structured pathway for employees to advance in their careers.

TechAMP combines in-person lab instruction at various collaborating institutions with online lectures from MIT faculty and interactive simulations. Participants also engage in capstone projects that focus on real manufacturing challenges within their firms, promoting cost-saving solutions. The program targets the emerging role of the “technologist,” a distinction that bridges the gap between traditional engineer and technician roles.

John Liu, a principal research scientist in MIT’s Department of Mechanical Engineering, emphasized the importance of this new educational pathway. “We think there’s a gap between the traditional worker categories of engineer and technician, and this technologist training fills it,” Liu stated. He highlighted the need for workers to adopt a broader perspective on manufacturing processes, aiding in decision-making and system-wide thinking.

Collaboration Across Institutions

TechAMP launched with partnerships that include the University of Massachusetts at Lowell, Cape Cod Community College, and Ohio State University, among others. The inaugural cohort of over 70 students reflects a diverse group eager to advance their skills. Julie Diop, executive director of MIT’s Initiative for New Manufacturing (INM), noted the program’s role in reaching a new demographic of learners.

The Initiative for New Manufacturing, announced in May 2025, is a comprehensive effort to revitalize U.S. manufacturing. INM collaborates with various industry firms to embrace innovative manufacturing approaches. John Hart, head of MIT’s Department of Mechanical Engineering, expressed enthusiasm about TechAMP’s potential. “We hope that the program equips manufacturing technologists to be innovators and problem-solvers in their organizations,” he remarked.

TechAMP’s curriculum adopts a “hub-and-spoke” model. The core training revolves around fundamental manufacturing principles, while the spokes focus on specific areas such as mechatronics, automation programming, and digital manufacturing. This structure ensures that trainees grasp essential concepts applicable across various industries, fostering a more adaptable workforce.

Positive Impact on Workforce and Firms

Participants have reported positive experiences with the program. Nicole Swan, an employee at Proterial, described TechAMP as a “confidence booster,” opening her eyes to numerous career opportunities. The program’s capstone projects aim to create direct value for participating firms by addressing real-world challenges, making the investment in employee training potentially worthwhile.

Michael Trotta, CEO of Crystal Engineering, underscored the necessity of high skill levels in manufacturing roles that do not require four-year degrees. He praised TechAMP as a logical step in workforce development, emphasizing the financial benefits of upskilling employees to increase their earning potential from around $20 per hour to $40 or $50 per hour.

While the term “technologist” may not yet be common in every manufacturing facility, MIT’s initiative aims to reshape this perception. Diop compared the role to that of a nurse practitioner in medicine, bridging gaps and enhancing service delivery. She believes that by formalizing pathways to such roles, TechAMP can transform the landscape of manufacturing jobs, making them more appealing and viable for individuals without traditional university degrees.

As TechAMP continues to evolve, MIT officials, including Liu and Diop, are exploring partnerships with educational networks in manufacturing-heavy states. There is a growing interest from manufacturers looking to engage with the program, indicating a strong demand for skilled workers in the industry. Liu noted, “There’s been a lot of excitement so far, and it’s coming from organizations eager to learn more.”

With its innovative approach and collaborative framework, TechAMP is poised to make a substantial impact on the future of manufacturing education and workforce development in the United States.

-

Science4 weeks ago

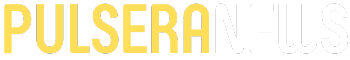

Science4 weeks agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Top Stories2 months ago

Top Stories2 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

Politics2 months ago

Politics2 months agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

World2 months ago

World2 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

World2 months ago

World2 months agoMass Production of F-35 Fighter Jet Drives Down Costs

-

World2 months ago

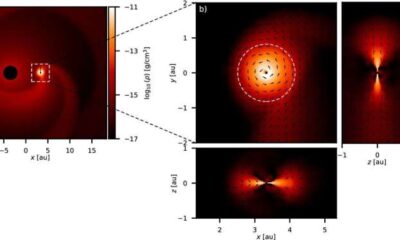

World2 months agoElectrification Challenges Demand Advanced Multiphysics Modeling

-

Business2 months ago

Business2 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Science2 months ago

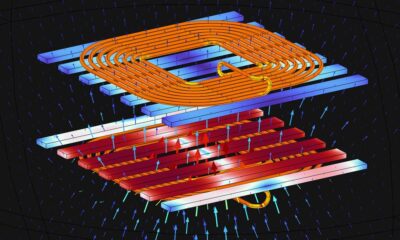

Science2 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Top Stories2 months ago

Top Stories2 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Entertainment2 months ago

Entertainment2 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Health2 months ago

Health2 months agoGavin Newsom Critiques Trump’s Health and National Guard Plans

-

Business2 months ago

Business2 months agoUS Government Denies Coal Lease Bid, Impacting Industry Revival Efforts