Science

Radboud Chemists Innovate in Bio-Based Materials Using AI and Robots

Researchers at Radboud University are pioneering a significant shift in the chemical industry by developing bio-based materials to replace traditional fossil fuel-derived products. This initiative addresses the urgent need for sustainable alternatives in various applications, including medicines, plastics, and paints. The project, part of the larger Big Chemistry programme, leverages advanced technologies such as artificial intelligence (AI) and robotics to expedite this transition.

The move from fossil-based to bio-based materials poses a complex challenge. The goal is to replace raw materials derived from oil without compromising the quality of the end products. Professor Wilhelm Huck, who specializes in physical-organic chemistry at Radboud University, highlights the intricacies of this transition. He explains that optimizing properties involves not just individual molecules but rather the interactions within mixtures. “You don’t want to optimize the properties of a single molecule, but of a mixture,” Huck states. This approach demands an understanding of molecular behavior and interactions, which can be unpredictable and complex.

The challenge is compounded by the sheer volume of potential interactions between raw materials. Huck notes that the chemistry involved is often “non-additive.” For instance, dissolving multiple sugar cubes in water may yield predictable results, but combining different molecules does not guarantee a straightforward outcome. With suppliers offering thousands of components for cleaning products, cosmetics, and more, the possibilities for interactions quickly escalate into the hundreds of millions. To navigate this complexity, researchers require robust models that can predict the properties of these mixtures based on extensive experimental data.

In response to these challenges, three projects have recently received grants under the National Growth Fund to explore bio-based solutions. Led by Huck, alongside chemists Mathijs Mabesoone and Peter Korevaar, these initiatives focus on the development of bio-based materials for applications such as paints and soaps.

Korevaar’s research, in collaboration with Van Wijhe Verf, aims to create paints that maintain essential qualities like waterproofing while utilizing bio-based ingredients. He emphasizes that achieving the right mixture is crucial: “Paint has to mix well. That mixture has to remain stable. It must not be too watery or too viscous.” This project highlights the need for extensive experimental data to ensure that new formulations meet stringent performance standards.

Mabesoone’s project focuses on soaps, working with Croda International. He explains that the cleaning efficacy of soap can vary greatly depending on its formulation. “In mixtures of soaps, that same property can suddenly occur at a hundred times lower concentration,” he notes. This unpredictability necessitates the collection of detailed measurements to build a comprehensive database that can inform predictive models.

The third grant supports research into polymers, which are large molecules often found in mixtures. Huck points out that insufficient data hampers theoretical calculations for these materials. By collaborating with organizations like TNO and Van Loon Chemical Innovations, the team aims to gather more data to refine AI models and enhance their predictive capabilities.

A key component of these projects is the use of robotics to generate vast amounts of unique data. A large robot lab is slated to open at the Noviotech Campus in Nijmegen by the fall of 2026. In the meantime, smaller robots are already in operation, continuously conducting measurements. Mabesoone describes the process: “You supply such a robot with a few samples of basic solutions, and then you put it to work testing, mixing, and measuring.” This automated approach allows researchers to explore a wider range of combinations than previously possible.

As these projects progress, the question arises: what will consumers experience as a result of this research? Huck reassures that if the transition is successful, consumers may not notice significant changes in their products. “If we don’t do this, you may find that at some point you can no longer get certain products because they contain substances that are no longer permitted or available,” he explains. In the long run, consumers can expect more biodegradable products without sacrificing quality. The integration of robotics and AI could potentially lead to the discovery of entirely new properties, enhancing the performance of everyday items.

As the work at Radboud University unfolds, it represents a critical step towards a more sustainable future in materials science, balancing innovation with ecological responsibility.

-

Science4 weeks ago

Science4 weeks agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Top Stories2 months ago

Top Stories2 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

Politics2 months ago

Politics2 months agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

World2 months ago

World2 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

World2 months ago

World2 months agoMass Production of F-35 Fighter Jet Drives Down Costs

-

World2 months ago

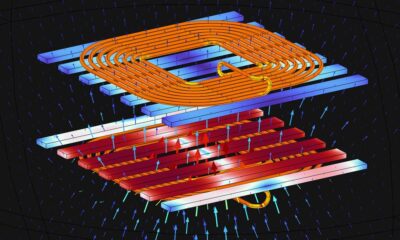

World2 months agoElectrification Challenges Demand Advanced Multiphysics Modeling

-

Business2 months ago

Business2 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Science2 months ago

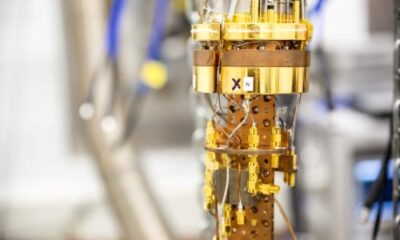

Science2 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Top Stories2 months ago

Top Stories2 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Entertainment2 months ago

Entertainment2 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Health2 months ago

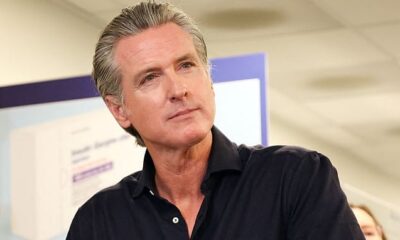

Health2 months agoGavin Newsom Critiques Trump’s Health and National Guard Plans

-

Business2 months ago

Business2 months agoUS Government Denies Coal Lease Bid, Impacting Industry Revival Efforts