Science

Research Team Achieves 20.02% Efficiency in Organic Solar Cells

A research team has successfully developed organic solar cells (OSCs) that achieve a power conversion efficiency (PCE) of up to 20.02%. This milestone was made possible through the introduction of novel giant acceptors featuring an oxygenated linker. The study, published in Advanced Materials, highlights the potential of these nonhalogenated-processed OSCs for next-generation photovoltaic technology.

OSCs stand out for their lightweight design, mechanical flexibility, and low-cost fabrication. These characteristics make them appealing candidates for renewable energy solutions. Traditional OSCs, however, depend on low-boiling-point halogenated solvents to attain high efficiencies. This reliance presents a significant barrier to mass production due to the solvents’ high volatility. While alternatives like toluene and o-xylene offer a more suitable option for scaling production, they often compromise efficiency by resulting in poor morphology.

Innovative Solutions in Organic Solar Cell Production

To overcome these challenges, the team, led by Prof. Ge Ziyi from the Ningbo Institute of Materials Technology and Engineering of the Chinese Academy of Sciences, employed toluene to streamline the fabrication process. This approach is tailored for scalable production of organic photovoltaics. The researchers introduced two giant guest acceptors, known as G-1O and G-3O, into blends of PM6:BTP-eC9.

The introduction of these acceptors extended the crystallization time of the blend, which effectively suppressed excessive aggregation while enhancing phase separation. Both G-1O and G-3O maintain the advantages of Y-derivative acceptors, including precise molecular architectures and excellent photoelectric properties. This leads to an optimized active layer morphology conducive to better performance.

Performance comparisons revealed that G-1O, characterized by its shorter oxygenated side chain, improved molecular planarity. This structural enhancement enabled a more homogeneous phase distribution, promoting efficient charge transfer and reducing voltage loss. The ternary device utilizing G-1O achieved a PCE of 19.90%, significantly outperforming the G-3O-based device, which reached a PCE of 17.90%.

To further augment the performance of the G-1O-based device, the researchers applied a 100 nm anti-reflection coating (ARC) layer, resulting in the notable efficiency of 20.02%.

Scalability and Environmental Benefits

In addition to high efficiency, the researchers successfully fabricated a 15.6 cm² large-area module using the PM6:BTP-eC9:G-1O system. This module achieved a PCE of 16.97% and notably contained no dead zones, underscoring the technology’s scalability and eco-friendly processing advantages.

This groundbreaking work establishes a viable pathway for the development of high-performance OSCs utilizing nonhalogenated solvents. The findings emphasize the significant potential for commercial applications in the photovoltaic sector, paving the way for more sustainable energy solutions.

-

Science4 weeks ago

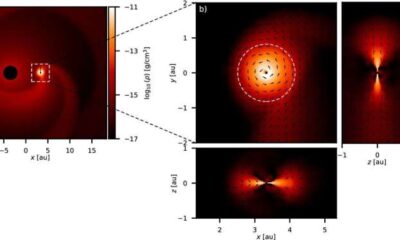

Science4 weeks agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Politics2 months ago

Politics2 months agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

Top Stories2 months ago

Top Stories2 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

World2 months ago

World2 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

World2 months ago

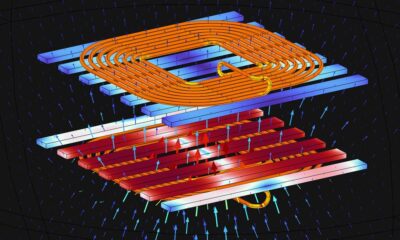

World2 months agoElectrification Challenges Demand Advanced Multiphysics Modeling

-

World2 months ago

World2 months agoMass Production of F-35 Fighter Jet Drives Down Costs

-

Business2 months ago

Business2 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Science2 months ago

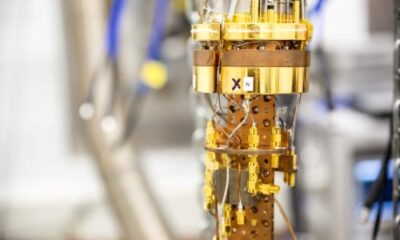

Science2 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Top Stories2 months ago

Top Stories2 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Entertainment2 months ago

Entertainment2 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Business2 months ago

Business2 months agoUS Government Denies Coal Lease Bid, Impacting Industry Revival Efforts

-

Health2 months ago

Health2 months agoGavin Newsom Critiques Trump’s Health and National Guard Plans