World

Boeing Begins Wing Assembly for 777-8F Freighter, Eyes 2028 Launch

Boeing has officially commenced wing assembly for the Boeing 777-8F Freighter, marking a critical milestone in the development of this advanced cargo aircraft. Recognized as the world’s most capable twin-engine freighter, the 777-8F is positioned to enhance Boeing’s standing in the competitive cargo market. The initial wing spars, measuring over 100 feet each, have been successfully assembled with their corresponding skin panels at Boeing’s Composite Wing Center located in Everett, Washington.

Significant progress is also being made by Boeing’s partners in Japan, including Mitsubishi Heavy Industries, Kawasaki, and Subaru. These companies are integral to the assembly process, contributing to the overall advancement of the 777-8F program.

Production Timeline and Industry Impact

This latest development follows Boeing’s earlier announcement regarding a delay in the entry into service for the 777-8F, now set for March 2028. The manufacturer plans to cease production of the Boeing 767 freighter by 2027, which could reshape the near-term widebody cargo landscape.

Overall wing assembly is progressing well, with Boeing confirming through a recent LinkedIn update that the fabrication of the wing spars and skins is on schedule. Reports from industry observers corroborate this progress, noting the use of robotic drilling techniques in the assembly process. Despite these advancements, the delay in service entry emphasizes the importance of timely execution in Boeing’s freighter industrial strategy.

Strategic Significance and Financial Considerations

The initiation of wing assembly not only signifies a key step in manufacturing but also underscores the strategic importance of the 777-8F platform. This aircraft leverages advanced composite materials and the cutting-edge GE9X propulsion systems, enhancing its performance and efficiency. The 777-8F is designed to compete effectively with emerging models, such as the Airbus A350F, which could attract airlines and freight integrators.

The delayed entry into service poses risks for Boeing, as it will create a tighter gap between the existing Boeing 767F and the new 777-8F. This could prompt airlines to consider alternatives if Boeing fails to streamline its production timeline. The current state of the cargo market raises concerns about future capacity, positioning Boeing to capitalize on the next upcycle with a high-capacity, long-range freighter.

From a financial perspective, achieving these production milestones will be crucial. Any further delays in the certification process for the 777X series could escalate costs significantly. Meeting the production checkpoints is essential to maintaining customer confidence and securing additional orders in an increasingly competitive market.

While the 777-8F is not designed for passenger transport, its production indirectly influences passenger airlines. Smooth production processes for the freighter variant support a shared industrial base that benefits the passenger versions of the 777X. In the meantime, cargo capacity on passenger aircraft remains vital for airline revenues, and the introduction of the 777-8F is expected to enhance airlines’ cargo capabilities.

Overall, the progress in wing assembly for the Boeing 777-8F Freighter positions the company for future success in the cargo sector, while also serving to reinforce its established leadership in the widebody freighter market.

-

Science4 weeks ago

Science4 weeks agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Top Stories2 months ago

Top Stories2 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

Politics2 months ago

Politics2 months agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

World2 months ago

World2 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

World2 months ago

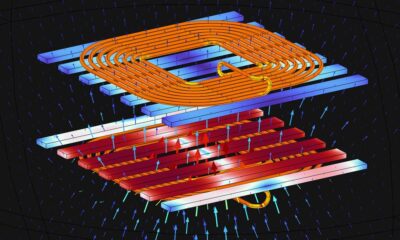

World2 months agoElectrification Challenges Demand Advanced Multiphysics Modeling

-

World2 months ago

World2 months agoMass Production of F-35 Fighter Jet Drives Down Costs

-

Science2 months ago

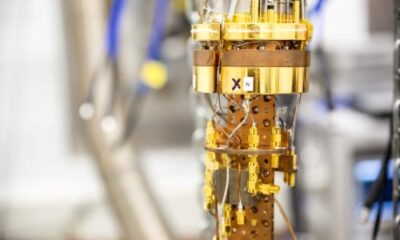

Science2 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Business2 months ago

Business2 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Top Stories2 months ago

Top Stories2 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Entertainment2 months ago

Entertainment2 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Health2 months ago

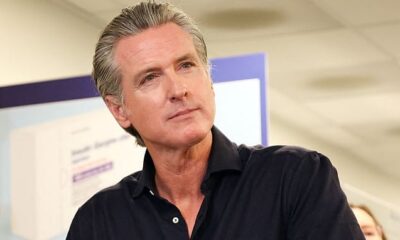

Health2 months agoGavin Newsom Critiques Trump’s Health and National Guard Plans

-

Business2 months ago

Business2 months agoUS Government Denies Coal Lease Bid, Impacting Industry Revival Efforts