World

Mass Production of F-35 Fighter Jet Drives Down Costs

The mass production of the Lockheed Martin F-35 Lightning II fighter jet has significantly reduced its per-unit costs, making it economically appealing compared to other advanced fighter jets. Despite facing scrutiny regarding delays and budget overruns, the F-35’s production numbers remain unrivaled, with the program set to deliver between 170 and 190 jets in 2025. This production scale has allowed Lockheed Martin to maintain relatively low flyaway costs for each aircraft.

Unmatched Production Rates

The F-35 program is characterized by its impressive production capabilities. Lockheed Martin has targeted a sustained output of over 156 jets annually. In 2024, the company delivered 110 F-35s, including both new builds and previously stored aircraft. By 2025, Lockheed aims to surpass the milestone of delivering 1,200 F-35s across all variants, including the F-35A, F-35B, and F-35C.

In contrast, other nations face challenges in delivering comparable fighter jets. For instance, France’s Dassault struggles to produce even two dozen Rafale jets annually, while Russian production numbers remain unclear but are estimated to be in the low dozens across all fighter types. The production capacity of the F-35 is a significant advantage in the competitive landscape of military aviation.

Cost Efficiency through Mass Production

The flyaway cost of the F-35 has been notably low. Lockheed Martin recently finalized a deal with the United States for production Lots 18 and 19 valued at $24.29 billion for 296 jets. This equates to an average cost of approximately $82.4 million per aircraft, potentially making the F-35 more affordable than other advanced fighters like the F-15EX and Eurofighter Typhoon.

While the initial purchase prices for the F-35 are lower than those of many competitors, the overall expenses can rise considerably due to sustainment costs. These include maintenance, spare parts, training, and advanced systems necessary for combat readiness. For example, the Czech Republic reportedly paid $208.3 million for its aircraft, while Romania incurred costs of $225 million each.

The lifespan costs associated with the F-35 are also substantial, reflecting the requirements for ongoing maintenance and infrastructure. Countries like the United States, the United Kingdom, and Israel often prefer a mix of fifth and fourth-generation fighters to balance costs and capabilities.

The F-35’s success can be attributed to both high domestic demand in the United States and significant international interest. Nations such as Japan, the United Kingdom, and Italy are among the top customers. The aircraft’s export status as the only fifth-generation fighter jet available to foreign militaries further enhances its appeal. Potential buyers, including Morocco and Indonesia, are eager to procure the F-35, although some, like Portugal and Spain, have expressed concerns over the program.

In summary, the combination of mass production and strategic pricing has positioned the F-35 as a leader in the fighter jet market. Lockheed Martin’s ability to deliver large quantities of these advanced aircraft not only drives down costs but also reinforces the F-35’s status as a preferred choice for modern air forces around the world.

-

Science3 months ago

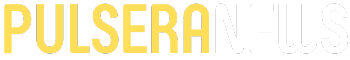

Science3 months agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Science3 months ago

Science3 months agoDoctoral Candidate Trivanni Yadav Advances Battery Research at UTulsa

-

Top Stories4 months ago

Top Stories4 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

World4 months ago

World4 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

Sports3 months ago

Sports3 months agoNASCAR Faces Fan Backlash as Steve Phelps’ Texts Surface

-

Business4 months ago

Business4 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Top Stories4 months ago

Top Stories4 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Politics4 months ago

Politics4 months agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

Science4 months ago

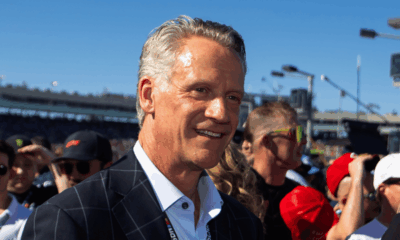

Science4 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Entertainment4 months ago

Entertainment4 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Science4 months ago

Science4 months agoRemembering David E. Brest: A Life Dedicated to Nature and Family

-

Entertainment4 months ago

Entertainment4 months agoPaul Giamatti Reveals Villainous Role in Star Trek: Starfleet Academy