Science

Why Tool Geometry Remains Crucial in Advanced Manufacturing

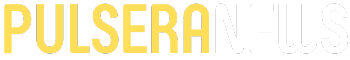

Recent advancements in manufacturing technology, particularly with the integration of robotics and smart CNC controls, have led to the belief that tooling is a secondary consideration. Despite these innovations, the foundational aspect of tool geometry remains essential for ensuring optimal cutting performance. This article examines the vital role that tool geometry plays in modern production environments, particularly in relation to automated systems.

Understanding the Importance of Tool Geometry

While robots and advanced CNC controls automate processes and adapt conditions in real time, they cannot change the fundamental physics of machining. Factors such as helix angles, rake angles, flute count, and corner geometry still govern the cutting forces, heat generation, chip flow, and surface finish. If these geometric parameters are not optimized, the sophisticated “smart” systems may struggle to maintain a stable and productive operation.

According to research conducted by the National Institute of Standards and Technology (NIST), successful Industry 4.0 projects rely on pairing robotics with CNC machinery and metrology. These systems study how artificial intelligence (AI) and sensors adjust machining conditions in real-time. However, the effectiveness of these systems hinges on starting with an appropriate cutting tool. AI-enhanced analytics can improve a sound process but cannot compensate for poor geometry choices.

Effects of Geometry on Manufacturing Efficiency

In environments where high-mix job shops automate processes, the choice of tool geometry is critical. For example, a cell might switch from machining stainless steel brackets in the morning to aluminum housings in the afternoon. Although CNC parameters are adjusted programmatically, the actual performance of the setup is heavily influenced by tool geometry.

Research indicates that even minor adjustments to edge radius, rake angle, and helix angle can significantly impact cutting forces and surface quality. A recent study confirmed that optimizing tool micro-geometry not only reduced cutting forces but also improved surface roughness and tool longevity across various machining tasks. Such sensitivity is crucial for maintaining stable production, especially in robot-fed operations.

It is important not to treat a tool, such as “a 10 mm carbide end mill,” as a uniform category in a database. Variations in helix angle or flute count can lead to distinctly different behaviors during machining. For instance, a high-helix, polished three-flute tool is more suitable for aluminum than a general-purpose four-flute design, which may lead to issues like chip packing during operations.

When robotics are involved, ensuring process robustness becomes more essential than merely maximizing cycle times. Unlike human operators, who can detect and respond to subtle changes in performance, robots continue to load parts regardless of underlying issues. Thus, tool geometry is the frontline defense against silent failures. For example, using a small corner radius when profiling hard stainless steel can minimize stress at the tool tip, reducing chipping risks and maintaining dimensional accuracy throughout production runs.

Integrating Geometry into Advanced Manufacturing Practices

For manufacturers already investing in smarter CNC and robotics, enhancing how they formalize tool geometry decisions can yield significant benefits. One effective approach is to standardize “tool families” based on material and operation, rather than solely on diameter. For example, for aluminum machining, specifying high-helix, polished three-flute tools with small corner radii can yield better performance for both roughing and finishing tasks.

Additionally, it is essential to incorporate geometry considerations into process approval workflows. When introducing a new part into a robotic cell, it is vital to assess not just feeds and speeds, but also helix angles, flute counts, and corner geometries for primary cutters. Questions to consider include whether the flute configuration can effectively clear chips in a specific pocket, if the corner design is robust for the intended engagement, and whether the edge preparation aligns with the material and coolant strategy.

Over time, manufacturers should document which tool geometries consistently yield superior results—whether in terms of better surface finishes or fewer overload alarms. These insights can help develop a library of geometries that align with the goals of automation, ultimately enhancing efficiency and productivity.

The integration of smart CNC controls and industrial robots can only optimize processes when the underlying tool geometry is sound. By recognizing geometry as a fundamental design decision rather than an afterthought, manufacturers can maximize the benefits of every technological advancement they implement on the shop floor.

-

Science3 months ago

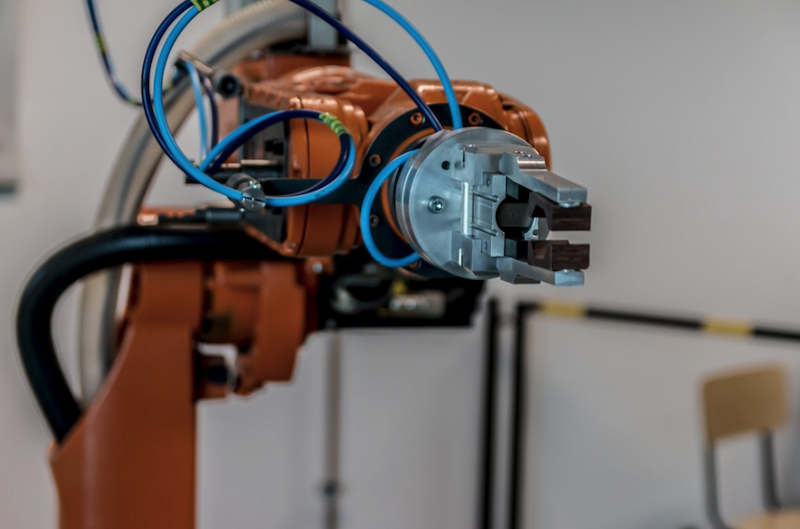

Science3 months agoALMA Discovers Companion Orbiting Giant Red Star π 1 Gruis

-

Science3 months ago

Science3 months agoDoctoral Candidate Trivanni Yadav Advances Battery Research at UTulsa

-

World4 months ago

World4 months agoGlobal Air Forces Ranked by Annual Defense Budgets in 2025

-

Top Stories4 months ago

Top Stories4 months agoNew ‘Star Trek: Voyager’ Game Demo Released, Players Test Limits

-

World4 months ago

World4 months agoMass Production of F-35 Fighter Jet Drives Down Costs

-

Sports3 months ago

Sports3 months agoNASCAR Faces Fan Backlash as Steve Phelps’ Texts Surface

-

Business4 months ago

Business4 months agoGold Investment Surge: Top Mutual Funds and ETF Alternatives

-

Top Stories4 months ago

Top Stories4 months agoDirecTV to Launch AI-Driven Ads with User Likenesses in 2026

-

Politics4 months ago

Politics4 months agoSEVENTEEN’s Mingyu Faces Backlash Over Alcohol Incident at Concert

-

Science4 months ago

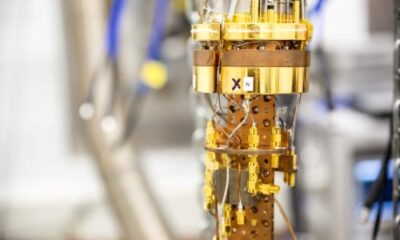

Science4 months agoTime Crystals Revolutionize Quantum Computing Potential

-

Entertainment4 months ago

Entertainment4 months agoFreeport Art Gallery Transforms Waste into Creative Masterpieces

-

Science4 months ago

Science4 months agoRemembering David E. Brest: A Life Dedicated to Nature and Family